|

Click here to return to Website Home page |

(Transcript from Transport Journal 1958)

Gosport and Fareham's Deutz-engined bus is

quiet and smooth in operation

Reference in our July 4th issue to the

Gosport & Fareham Omnibus Company's Provincial bus with its

air-cooled diesel engine has now been followed by a visit to Fareham where The

Transport Journal was able to see the vehicle, ride in it and talk to the

man who brought it into being - H. Orme White, Director, Manager and Engineer of

the Gosport & Fareham undertaking.

As previously stated the conversion has been

made to a 10-year-old Guy Arab double-decker having a new fully fronted body

built by Reading & Co Ltd of Portsmouth. Bodywork is generally orthodox with

56 seats provided, but there are variations to the front end, The distinctive

radiator grille now standardised on full-front bodies in the Provincial fleet

hinges back completely on the bus with the Air-cooled diesel to present a

secondary shield In which is a sliding panel lined up with the engine blower.

Engine

installation - grille panel opened

At present the sliding panel is being

adjusted from day to day to assess the ideal air input. The other unusual aspect

of the bodywork - although it is in fact standard practice on Provincial buses -

is the use of the area to the nearside of the cab as luggage space: the N/S door

is marked "luggage compartment" and as many as 12 folding pushchairs

have been carried in it.

The 6 cylinder Deutz Air-cooled Diesel

(described later in this article) is rubber mounted at four points and no

difficulty was experienced in fabricating the necessary brackets to suit both

engine and chassis, although it was necessary to tilt the engine by some 10

degrees to position it the space available. As with most engines there was some

judder to the unit on starting, slow tick over, and stopping but one simple

rubber at the offside front mounting point has completely obviated this.

Considerable attention has been paid to

engine insulation - both for heat and sound - and the engine compartment is

lined with one and a half inch glass fibre, while additionally there is a

quilted cover over the engine compartment. This has proved very successful: the

engine is very quiet - certainly no noisier than a comparable water-cooled unit

-while little or no heat is transferred to the driver's cab. Thoughts that it

might be difficult to keep the engine operating temperature low enough have also

proved wrong for, if anything, the temperature is on the low side. On the hot

summer day at the beginning of July when we travelled in the bus the cab

temperature was 80 degrees F and that of the engine 140 degrees F.

Vibration is also noticeably low. At engine

idling speed, when vibration is often noticeable in the seats and stanchions,

there was complete absence of movement: this may be accounted for by the Deutz

engines comparatively high idling speed of 500 RPM. Fuel and oil consumption

figures approximate closely to the fleet average.

The Deutz Air-cooled Engine

The Deutz engine is the F6L 514 six-cylinder

in-line model. Air cooling, which is the main interest of British operators, is

effected by a large capacity fan on the offside (vee belt driven), with ducting

to give a flow from starboard to port through cylinder fins. Cylinder barrels

are separate units with detachable heads, the securing b9olts passing through

the heads and into the crankcase. The barrels are spigotted top and bottom for

location and made in cast iron, while heads are die-cast in light metal. Gas

sealing is effected by rubber rings at the lower end and by a joint face at the

top. Air and exhaust passages are on the same side to the head, opposite the

injector and heater plug. Gudgeon pins are offset towards the exhaust side for

smooth running. The drop-forged connecting rods are H section and the big ends

are split diagonally: bearings are lead-bronze shell type.

Of high-grade steel, the crankshaft runs in

seven steel-backed lead-bronze bearings. The camshaft and tappets are carried in

the crankcase and light alloy push rods operate the overhead valves; eats and

valve guides are renewable. Rocker arms on bronze bushes and an oil tight cover

enclose the valve gear.

The thoroughness of German design is

evidenced by several safety measures built into the engine. For example a

temperature indicator is built into the cylinder head and this can be coupled to

either an audible warning device or a shut down mechanism. Similar devices are

operated by a simple spring mechanism attached to a the vee belt jockey wheel to

warn of any belt breakage. Lubricant is force fed by a gear pump driven from the

crankshaft, a secondary line feeding the camshaft and rockers. An oil cooler is

also provided. Fuel injection pump is by Bosch and is gravity fed, while the

engine incorporates a Deutz injection timing device and governor for idling and

maximum speed.

Various fuels may be used in this engine, the

normal one being gas oil, but the range includes brown coal fuel oil, tractor

fuel, kerosene, and petrol/lubricating oil mixture in the ratio 90%-10%. One

more unusual mixture is that of 99% motor spirit and 1% Kerobrisol, this latter

substance raising the ignition quality and cetane number of light fuels.

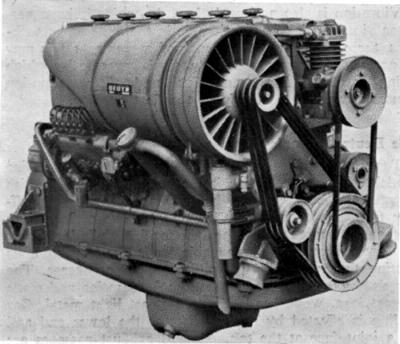

General

view of the engine

Conclusion

It is too early to decide whether the

air-cooled diesel engine will become widely accepted for British operation, but

certainly the first results are promising. Soundproofing more than obviates any

extra noise in operation and fuel consumption appears to be comparable with that

of similarly sized water-cooled diesels. Due regard must be given to the fact

that no radiator and attendant water cooling system is required; the complicated

gaskets are eliminated; that the cooling air reached a temperature of 176

degrees Fahrenheit and can be used for saloon heating; and that buses with air

cooled engines can be parked in the open in any weather, these factors must

carry considerable weight in the minds or manufacturers and operators.

Specification of Deutz F6L 514 Engine

|

No of cylinders |

6 in-line |

|

Injection principle |

Indirect :swirl chamber |

|

Maximum torque |

332 ft lb at 1,200 RPM |

|

BHP |

125 at 2,300 RPM |

|

MEP |

86.9 lb per square inch |

|

Bore and stroke |

4.125 inches X 5.5 inches |

|

Compression ratio |

17.8:1 |

|

Specific fuel consumption |

.396 lb/bhp/hr at 1,1200 RPM |

|

Starter |

12 volt |

|

Net weight |

1430 lb |

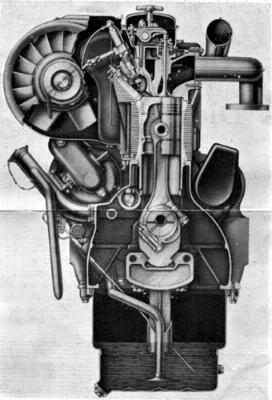

Cross-section through the engine

|

Click here to return to Website Home page |